Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Changzhou Rainbow Wonder International Trade Co.,Ltd.

caiboo@vip.126.com

+86-0519-89815151

Brand: Rainbow Wonder

Status: New

Applicable Industry: Manufacturing Plant, Other

Out-of-warranty Service: Video Technical Support, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Marketing Type: Hot Product 2019

Place Of Origin: China

Service System: Video Technical Support, Online Support

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Transportation: Ocean

Place of Origin: CHINA

Port: Shanghai

Payment Type: T/T,L/C

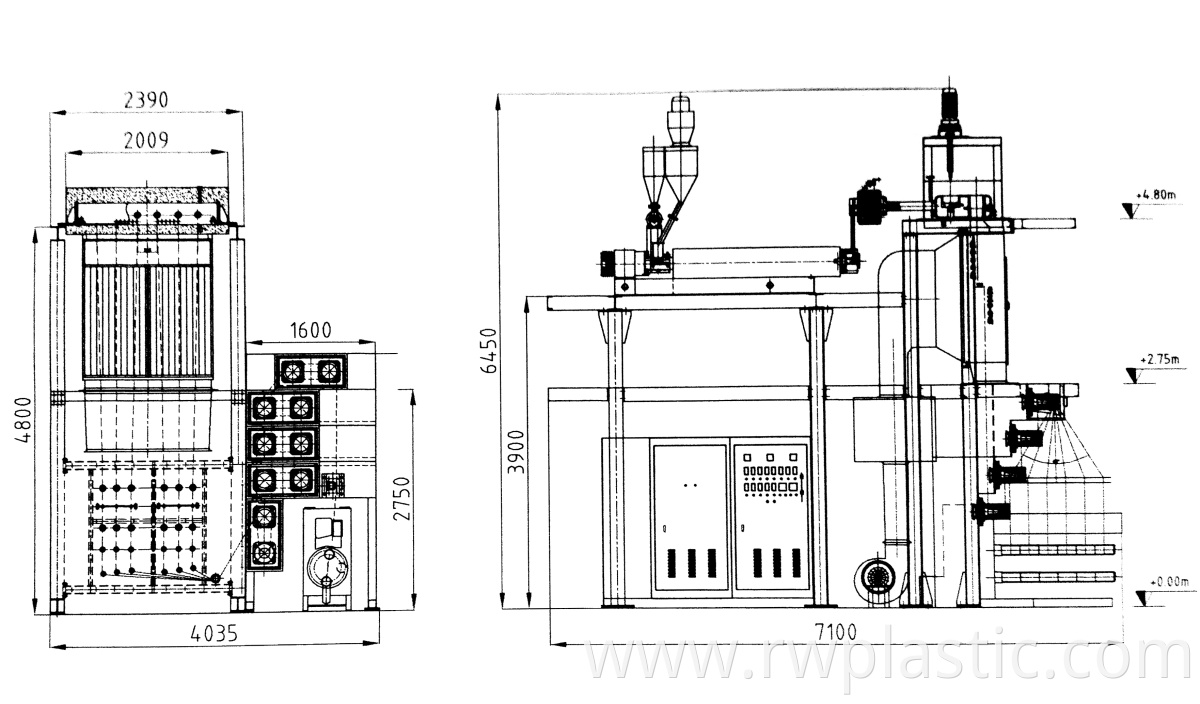

This project is designed for a layer of structure, which has the characteristics of less investment, shorter spinning process, and quick response;

Modular design of the host equipment, each module independent packaging, transport, combination and adjustment is simple,Convenient; net height of 7.5 meters of the plant can meet the requirements; the project from the beginning of the raw materials of polypropylene,After the screw extruder, high speed spinning drawing factory manufacturing equipment with deformation,Automatic switching winding machine, provide for the customer to produce high-quality high-strength polypropylene filament full drawing

Good equipment and technical service.

1)Screw:90mm L/D = 30:1 1 step 1 Winder

2)Dianel Range: 1000d/ and 500D/ are two roll spinning, 6 head spinning

3)Breaking strength: 6.5 ~ 7.5 g/d (this is the acceptance criteria of high tenacity)

4) Max.capacity: about1400KG/24hrs .

The PP Multifilament Spinning Main Machine Assemble

| item | Unit name | Specifications | quantity | remark |

| 1 | Granulate Mixing |

| 1set |

|

| 2 | Masterbatch injection and Convey Unit |

| 1set |

|

| 3 | Single Screw Extruder Main Machine | Screw:F90mm L/D = 30:1 | 1set |

|

| 4 | Spinning box | Stainless steel | 1set |

|

| 5 | Metering pump | 4 x 8 cc/rev | 1set |

|

| 6 | Side blowing device |

| 1set |

|

| 7 | Spinning channel | Stainless steel | 1set |

|

| 8 | Oiling device |

| 1set |

|

| 9 | Drawing Machine | 10 rollers | 1set |

|

| 10 | Spinning Unit of Electrical control cabinet |

| 1set |

|

| 11 | Drawing Unit of Electrical control cabinet |

| 1set |

|

| 12 | Winder |

| 1set |

|

| 13 | Winder Unit of Electrical control cabinet |

| 1set |

|

| 14 | Steel Frame |

| 1set |

|

2. Auxiliary equipment

| item | Auxiliary equipment | quantity |

| 1 | Vacuum Cleaning Furnace | 1 set |

| 2 | Ultrasonic Cleaning Machine | 1 set |

| 3 | High position oil mixing tank | 1 set |

| 4 | YG086C Yarn Measuring Reel | 1 set |

| 5 | YG020D-50 Single Yarn Strength Tester | 1 set |

| 6 | Electronic scale | 2 set |

| 7 | Electronic scale |

|

| 8 | Table | 1 set |

3.The other devices prepared by buyer self

| Air compressor and air storage tank | prepared by client self |

| Stable quality of cooling water after filter | Prepared by client self |

| Circulating cooling water | Prepared by client self |

| Power | Prepared by client self |

| 1. COMPRESSED AIR SYSTEM A) COMPRESSOR Capacity : 230 Nm3/hr (134 CFM) Pressure : 8 bar B) AIR DRYING UNIT Capacity : Matching compressor capacity as in point no. 1(A) above. Pressure : 8 bar Dew Point : + 5 °C (1% moisture) C) COMPRESSED AIR RECEIVER The air storage receiver of 1000 ltr. capacity and working pressure 10 bar to serve for compensation of supply peaks as well as for re-cooling of compressed air. Note: Optimum power consumption of Air Compressor can be achieved with variable drive rotary screw compressor having built-in dryer like GA 22 VSD model from M/s Atlas Copco. 2. CHILLING PLANT FOR COOLED WATER a) Recommended Capacity : 15 TR (45,390 Kcal/hr) b) Required Water Temp at M/c inlet. : 8 to 10oC. c) Approx. Water Temp at M/c outlet : 12 to 13oC. d) Water Flow rate : 200 LPM | Prepared by client self |

4.The spare parts and tools list

Annex1. Tools List (Supplied by seller)

| No. | Name | Quantity |

| 1 | Wrench for meatering pump | 1 set |

| 2 | Wrench for pump plate | 1 set |

| 3 | Tools for components disassembling | 1 set |

| 4 | Tools special for heat-stretching roller | 1 set |

| 5 | Inner hexagon spanner | 1 set |

| 6 | Open-ended wrench | 1 set |

| 7 | Cross screwdriver | 1 pcs |

| 8 | Slotted screwdriver | 1 pcs |

| 9 | Hammer | 1 pcs |

| 10 | Needle-nose plier | 1 set |

| 11 | Tools for components | 1 set |

| 12 | Scissors | 1 pcs |

| 13 | Adjustable wrench | 1 pcs |

| 14 | T-shaped wrench special for adjusting rollers | 1 set |

Annex 2. Spare parts list (Supplied by seller)

| No | Name | Quantity |

| 1 | Extrusion machine copper sealing gasket | 1 set |

| 2 | Melt pipe copper sealing gasket | 1 set |

| 3 | Components aluminum sealing gasket | 100 pcs |

| 4 | Components sealing filter | 1000 pcs |

| 5 | Components feed aluminum sealing gasket | 100 pcs |

| 6 | Transmission shaft for metering pump | 1 set |

| 7 | Metering pump shaft plug | 2 pcs |

| 8 | Safety pin for metering pump | 4 pcs |

| 9 | Screws special for metering pump | 2 set |

| 10 | Cast Aluminum heating ring for screw | 1 area |

| 11 | Flange electric heating coil | 1 area |

| 12 | Box heating rod | 4 pcs |

| 13 | Pressure spring platinum resistance for screw | 2 pcs |

| 14 | Platinum resistance for box | 1 pcs |

| 15 | Platinum resistance for lateral blowing | 1 pcs |

| 16 | Platinum resistance for hot roller | 10 pcs |

| 17 | Pressure sensor for extrusion head | 1 set |

| 18 | Drive reducer for metering pump | 1 set |

| 19 | Metering pump | 1 set |

| 20 | Low speed motor for hot roller | 1 set |

| 21 | High speed motor for hot roller | 1 set |

| 22 | Out disk for hot roller | 2 sets |

| 23 | Heating coil for hot roller | 2 sets |

| 24 | Solid state relay | 4 pcs |

| 25 | Control knob | 2 pcs |

| 26 | Control knob | 2 pcs |

| 27 | Triple switch | 1 pcs |

| 28 | Assembled 8-groove yarn-guide wheel | 10 sets |

| 29 | Oil spraying nozzle | 8 pcs |

| 30 | Yarn-guide hook for network device | 8 pcs |

| 31 | Pig tail shaped yarn-guide device | 8 pcs |

| 32 | 4-head network device | 2 pcs |

| 33 | 8-head network device | 2 pcs |

| 34 | Rabbit head shaped device | 100 pcs |

| 35 | Proximity switch | 2 pcs |

| 36 | Speed sensor | 2 pcs |

| 37 | Electric-magnetic valve | 2 pcs |

| 38 | Bearing of shaft for grooved drum | 1 set |

| 39 | Coils for grooved drum | 1 set |

| 40 | Atomizing silicone oil | 10 bottles |

| 41 | Pipe joints for water, oil and air | 2 sets for each |

| 42 | White grease | 1 box |

| 43 | Series of PU pipes | 5m for each kind |

| 44 | High temperature anti burning agent | 2 tank |

| 45 | Bush-hook 钩刀 | 1000PCS |

| 46 | Bobbin F94xF108x230mm | 2000 pcs |

| 47 | Sping Oil | 160KG |

The Consumables needed for one year production

| Item | Name | Quantity | Unit price | Total Price |

| 1 | Components sealing filter | 1000pcs |

|

|

| 2 | Bobbin F94xF108x230mm | 30000pcs |

|

|

| 3 | Sping Oil | 1000KG |

|

|

| 4 | Colding Masterpatch | 1000KG |

|

|

Parts list and quotation for normal production one year

(not include spare parts and tools with main machine)

| number | Name | Type | Quantity | Remark |

| 1 | Electric heater | Various specifications | Each 1 sets |

|

| 2 | Metering pump drive speed reducer | FTY1000-4/1:59 | 1 sets |

|

| 3 | Motor of drawing hot roll | 4 poles | 1 sets |

|

| 6 poles | 1 sets |

| ||

| 4 | Motor of leading roll | 4 poles | 1 sets |

|

| 5 | Oil pump drive speed reducer | FTY180-4/1:43 | 1 sets |

|

| 6 | Chuck for roll | 4 spinning | 1 pcs |

|

| 7 | All kinds of guider of porcelain pieces |

| 1 sets |

|

| 8 | Outside disk of hot roll |

| 1 pcs |

|

| 9 | heating coil of Hot roll |

| 1 pcs |

|

| 10 | Grooved drum coil for winding machine |

| 1 pcs |

|

| 11 | Motor of chuck of winding machine |

| 1 sets |

|

| 12 | Traverse of winding machine |

| 500 pcs |

|

normal production of a year of accessories ,the price is RMB 100,000.00。

Description: the use of simple packaging, not recycling。

Product Categories : PP Spinning Machine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.